Making Heathergems

Heathergems is and imaginative range of Scottish jewellery and giftware, made in Pitlochry, Scotland from natural heather stems.

Follow our step by step guide on how Heathergems are crafted from the heather on the hills to unique pieces of jewellery. We are the only manufacturers of this unique Scottish product anywhere in the world and our process has been refined to a delicate skill through over 50 years of crafting.

1. Collect the heather

The heather is collected from the Perthshire hills. As heather grows the stems become woody providing no nutrition to wildlife such as sheep, deer, birds, rabbits and hares. While underneath those long stems the ground becomes barren - natural regrowth unable to take place. There are vast areas of such moors across the highlands, but, this is the type of heather we select for Heathergems. So, as well as creating a valuable highland commodity we are helping - in a small way - to regenerate the landscape.

2. Cut the heather

So how does it move then, from moorland to jewellery. The whole process takes place in this building and begins as we store the heather and watch it carefully as it dries out.

We then cut the heather to length using a bandsaw.

3. Clean the heather

The bark is removed using a specially adapted shot blasting machine. The heather being tumbled while shot is fired at it to chip away the bark and leave the cleaned stems. The heather is then carefully graded by size and collected into bundles - a mix of different thicknesses of stem will help bind and strengthen the finished jewellery. The variety of stems is vital to make the block as solid as possible, a process requiring considerable experience.

4. Dye the heather

We then use dyes and colours carefully chosen to reflect the hues and shades of the heather moors and our stunning Scottish landscape.The stems are then put in a vacuum chamber into which a heated dye is released. It can take up to 2 days to get the dye fully into the heather.We then mix the dyed stems together to achieve the beautiful variations of colour and pattern unique to Heathergems.

Compress the stems

Next the stems are soaked in resin and subjected to 60 tonnes of pressure, the resin helping the stems to move as the block is compressed whilst binding the block together. The block is then put in an oven with a mild heat to help it set.The following day, the heather block is removed from the mould and the rough edges trimmed off.

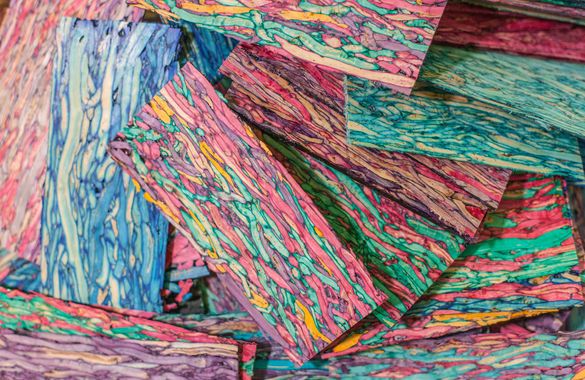

Slice the block

The block is then cut into individual slices of different thickness. The raw material for the Heathergems is now ready to be transformed into unique designs.

Individual pieces cut

Various shapes and sizes are programmed on a computer. The slices are then put into a computer-controlled cutting machine used to cut out the individual pieces.

Fill, sand, and shape

Any imperfections are filled, sanded, and shaped by the skilled craftspeople with each individual piece requiring great precision and delicate handling.

Lacquering the pieces

We then apply up to 5 coats of lacquer by hand to enhance the beautiful colours and patterns while producing a durable finish.

Fitting the pieces

Finally, we fit chains, ear wires, or set the finished jewellery into mounts.